In electronics, safeguarding signals from external interference is essential for maintaining stability and reliability. Effective shielding is particularly critical in environments with high levels of electronic noise. This article provides key recommendations for achieving optimal shielding on harness assemblies, focusing on best practices and proven techniques.

The importance of shielding:

Shielding protects electronic signals from electromagnetic interference (EMI) and radio frequency interference (RFI). Properly installed shielding prevents these disturbances from degrading signal quality. The material must be metallic and properly grounded through a metallic connector for effective shielding.

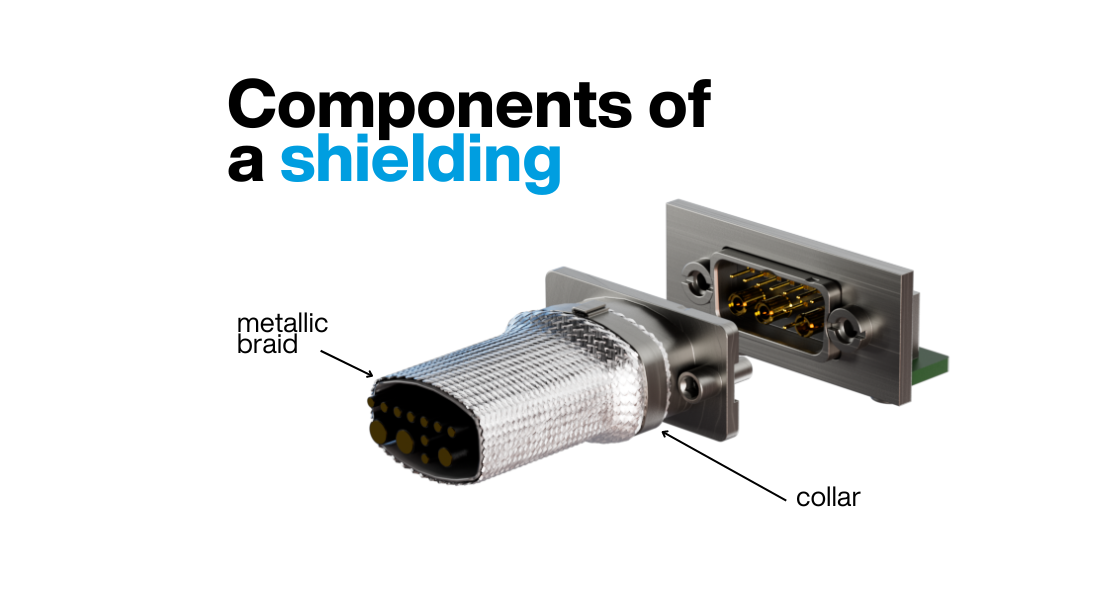

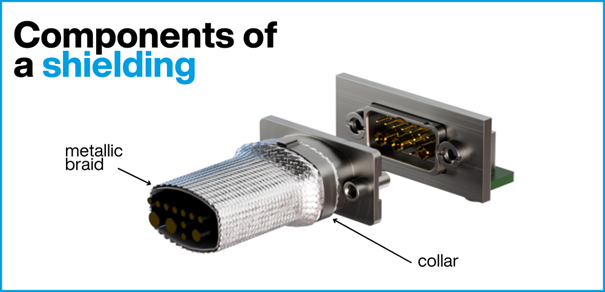

Essential components of shielding

Metallic shielding braid

Material compatibility: To ensure effective shielding, selecting compatible materials for the metallic braid and connector is essential.

Coverage rate: The braid should have a high coverage rate to maintain the shield's integrity when expanded over the connector and cable bundle.

Appropriate diameter: The braid diameter must fit the size of the cable bundle to ensure comprehensive protection.

- Metallic connector

Backshell connection: The braid must be securely connected to the metallic connector shell via a backshell, ensuring a robust and stable connection.

Connecting the metallic braid to the connector

- Using a metallic collar: A metallic collar is recommended to secure the braid around the connector's chimney. This ensures a strong connection and minimizes potential weak points where interference could penetrate.

- Maximizing contact points: To maximize contact points, the collar should press the braid firmly against the chimney. Adding knurling to the chimney can improve retention.

- Optimal chimney shape: A round or oval chimney shape is preferred as it allows the collar to fit well and ensures 360° contact, eliminating unprotected areas.

Testing and quality control

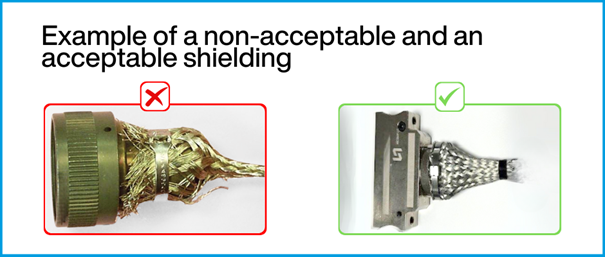

Laboratory testing and qualification: Validate the material choices and techniques through laboratory tests to ensure they meet transfer impedance (Zt) and resistance requirements. Transfer impedance (Zt), defined as Zt = Vin/Iout, measures a cable's ability to transmit a signal without electromagnetic interference (EMI) disruptions. Conduct laboratory tests specifically for transfer impedance to ensure optimal performance. A visual inspection following IPC A620 standards is also recommended to verify the quality of the shielding.

Production control: Rigorous inspections during production are necessary to ensure all assemblies meet the required standards. IPC guidelines can serve as a reference to determine acceptable practices.

Effective shielding on harness assemblies is vital for protecting electronic signals from interference. By following these recommendations, engineers can ensure their systems remain reliable and performant even in challenging environments.